BMS Car Deployment

(See latest update 5/3/2025 below)

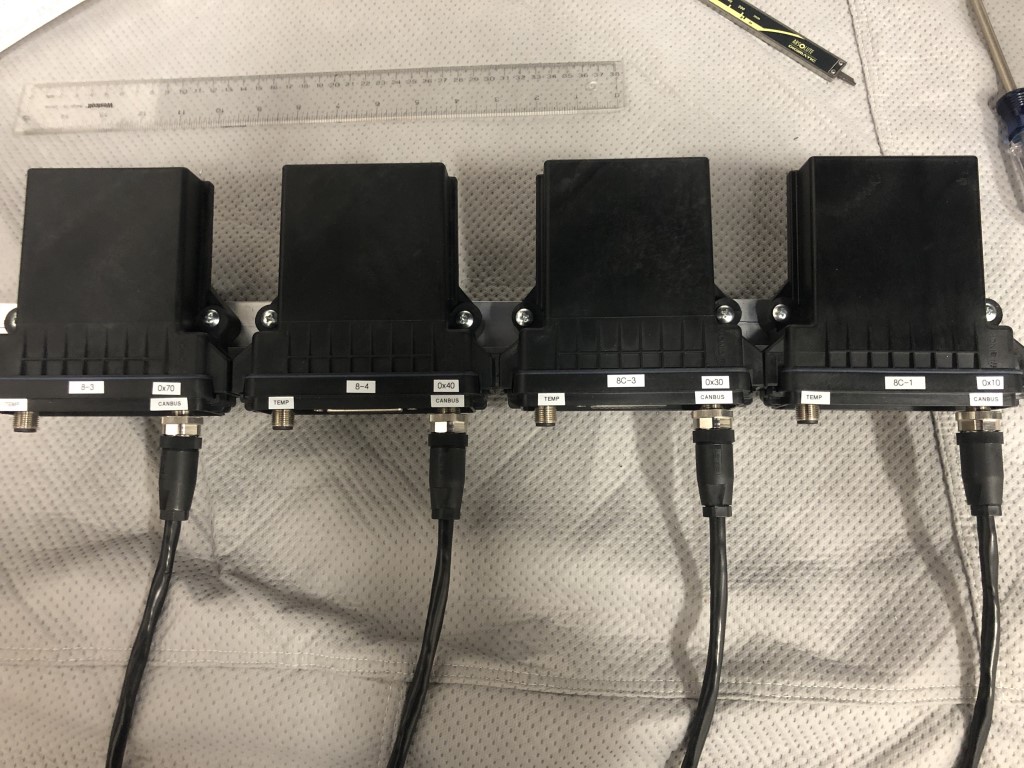

The four BMS units mounted in the CINCH enclosure are ready to go in the car. The CANBUS data and power cables have been made. Still working on the temperature measurement cables. The CINCH units are screwed to an aluminum 1"x1" rectangular tube that was drilled and cut to fit in the trunk battery box. The tube provides clearance for the bolts used to attach it to the battery box as well as the screws used to attach the enclosures. This mounting system is a test to see how everything is going to fit together and how all the wires are going to be managed.

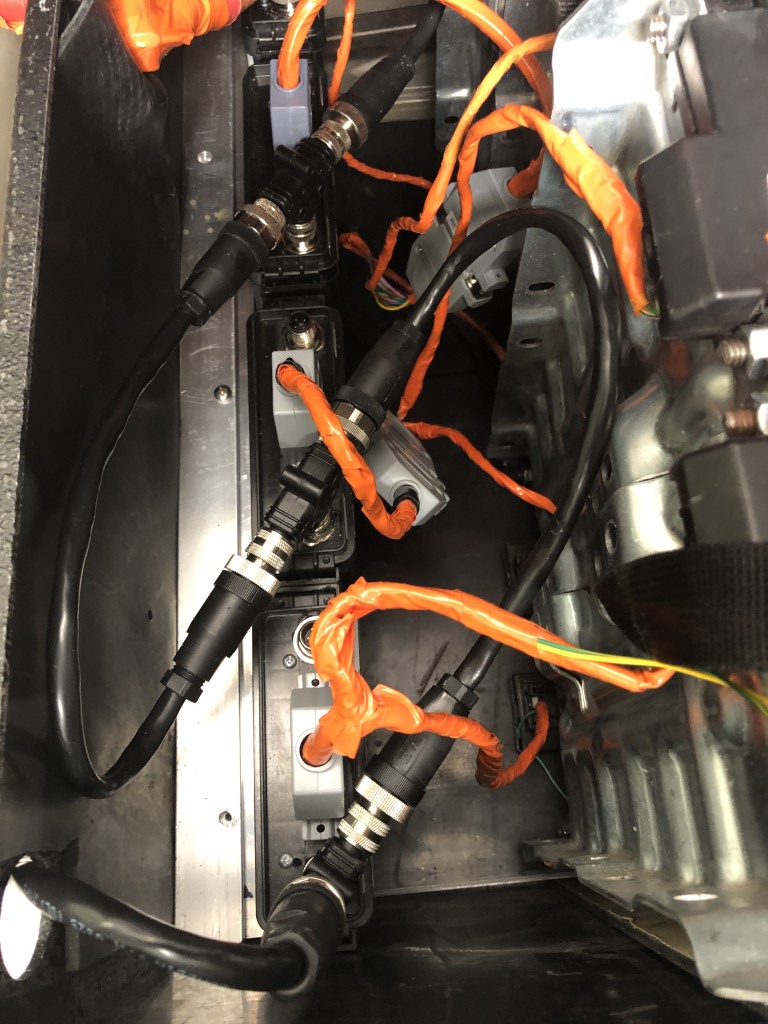

By mounting the BMS units inside the battery box negates the need to make the DB25 connectors any longer. The ones that are already connected to the batteries are used with a gender changer DB25 connector. Only the middle battery has to have a DB25 extension cable because that battery is wired in reverse order. I first tried to use the four 12mm wires shown above connected to each BMS in the battery box, but there is not enough room and it looked very cluttered. Plus I could not get all four wires though the hole in the side of the battery box. Using the 12mm tee connectors shown below have made the 12mm wiring more compact and only one wire has to come out to connect to all four BMS units. I need to add some cable management and strain relief to the one cable going though the side of the battery box.

This initial setup is okay for testing. The battery sense wires (orange) will have to have some kind of wire management now that they are going to be connected all the time. I might also install the screws in the DB25 connectors once everything is tested and working correctly. The 12mm cables for the temperature measurement still have to be installed.

These are the12mm tee connectors that made a cleaner installation. Here is the link to the data sheet.

Update 5/3/2025:

Installed wire management and all the temperature measurement cables. I used different 4-conductor cables for the temperature measurement. They were easier to connectorize with the 12mm connectors. I found I had to add a couple of threaded rods to hold the batteries tightly in the battery box. A while ago I had to cut the end of the box off when I added the fourth battery to the trunk box. I had a metal square tube as a strength member to hold the battery box together. I had to remove that tube where it was originally mounted. It was connected to the angle aluminum that the BMS units are attached to now. The threaded rod also makes it easy to adjust the compression on the box to hold the batteries so they don't move while driving.